Most people would expect to see 3D printing in full action when they go to Tonsley Innovation Centre; a place that has been the home of many engineering companies investing in this technology. Ernest has now made ACH Group Elkanah Retirement Village, located in Woodcroft – and his home, a place that not only you can see 3D printing in action, but you can learn and get tips on how to use it too.

Ernest Ames was brought up in Warwickshire, UK. Son of an electrical engineer, he was taught to build and fix things from an early age. “Growing up you were taught how to use tools and you would repair things yourself,” he says.

At the age of 34, Ernest moved to Adelaide where he secured a job with the Woods and Forest Department working for the Sawmill in Mt Gambier. In his spare time, he volunteered and designed furniture for the local community centre.

In his long career, Ernest has been an enthusiast to draw anything, from badges to buildings. “My late wife and I – you name it, we could do it. Between us two, we have built everything we had in our house.”

While in retirement, Ernest drawings were still in high-demand and he was asked to design Reg Smith’s new dairy. “I don’t see the point in stopping. I think when I retired, I worked more than when I was at work,” he says.

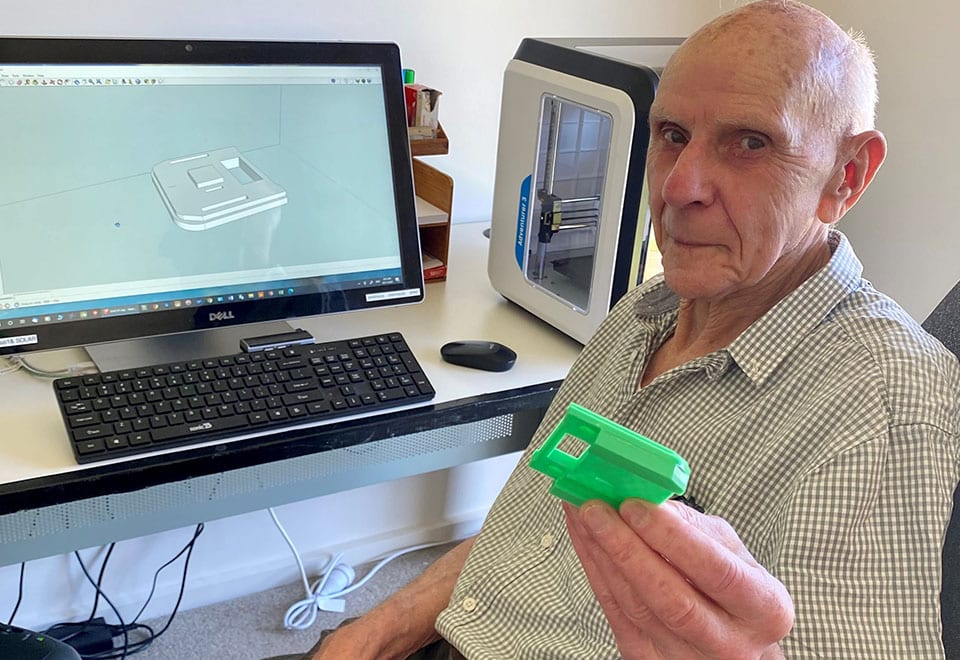

It was only recently that Ernest grew interested in 3D printing. He has two different 3D printers and often prints parts for his friends and neighbours. “3D printing is not as complicated as it might seem. It is 10 percent know-how and 90 percent patience”, he said.

“I think 3D printing is no different than printing a letter you type in your printer; the difference is that it prints in plastic. Most women of my generation have taken to 3D printing, because they had sewing or knitting machines and learnt how to use them. Today, they have no one to knit for but with a 3D printer, they could make toys for the grandchildren.

“There are great tools to help people get started and I am willing to guide those who would like to discover more about this technology and maybe replace the sewing to a 3D printer machine”, Ernest added.

Now, with two projects on the go – a power drill conduit for his next-door neighbour, and parts for a model train, Ernest’s passion for engineering, technology and helping others continue to showcase his multi-dimensional talents.